TECHNOLOGY

Water Tank Placement Foundation Construction Method

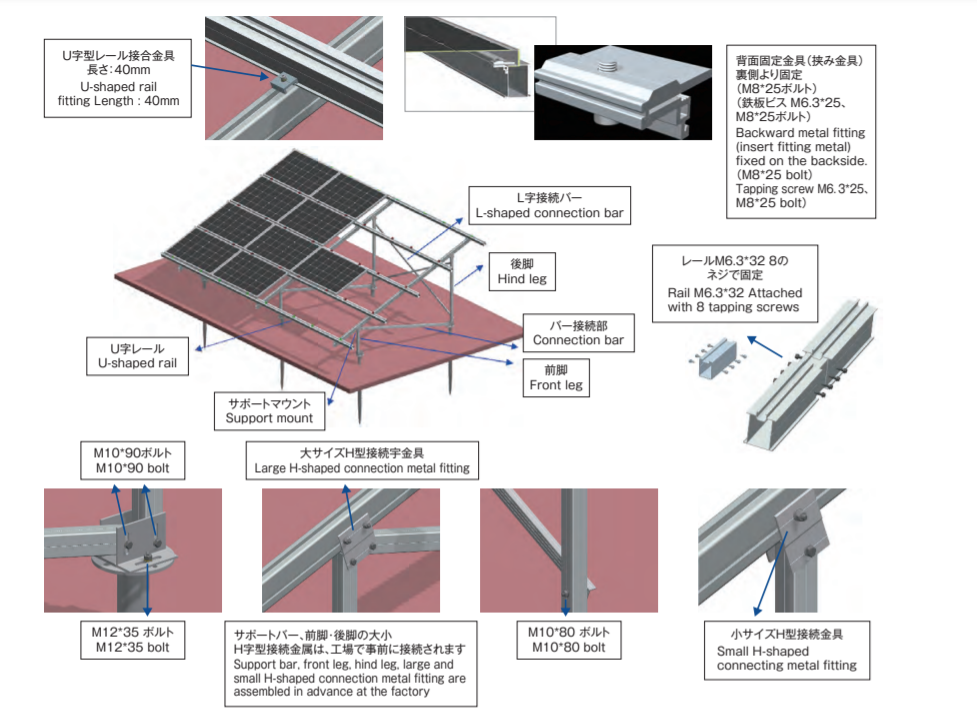

Placement Frame Unit Method

A total of 162 solar cells were installed in 9 units with 18 solar cells per unit. The wiring is kept in the cable rack (W=200) to improve the appearance.

The structure has a slope of approximately 3° to eliminate water puddle and is facing south.

Small power converter 9.9KW x 2 units Dedicated installation rack

Power converter foundation block 120×120×600

The rooftop is waterproofed with exposed asphalt, so the frame units are placed on top of t5.0 anti-vibration rubber.

The weight of each unit is 1000kg to withstand wind pressure. (Loading weight of 40kg/m²)

Screw Foundation Construction Method

Screw pile driving

Pull-out strength test

Frame set

Solar panel installation

Example of solar power

generation system installation

generation system installation

WORKS